Geek Out With Us

It’s been said more than once that it’s “awesome to walk in and see BlowHard engineers geeking out over numbers and diagrams.” Ummm…guilty as charged. We get excited when we have breakthroughs. Breakthroughs usually come in baby-steps. Therefore, it doesn’t really take too much to get us all giddy with excitement. This section is for those who share the same excitement for the “geeky” stuff. We hope you like it, and encourage any feedback or added conversation. You can write to us. We all have access to this account, and would be happy to hear from you!

Size Matters

“Size Matters” is a 4-part discussion about truck space, in the deployment process, performance, and keeping it simple.

1. ALL ABOUT THE FIT

2. GRAB-N-GO

3. Blow Harder

4. WE’RE EASY

We want to talk about why size matters when it comes to simplicity vs. complexity, and how the “extra” stuff can really add up.

K.I.S.S.

That oh-so-familiar acronym, “Keep It Simple Stu… Silly!” Creating high-performing tools that are easy and simple to use without compromising performance is a top BlowHard priority. From storage to portability, from deployment to maintenance, from start to finish, the entire process with BlowHard fans is made easy by design, with the firefighter in mind. In fact, “easy” is integrated into a BlowHard fan so the firefighter doesn’t have to even think about it.

Easy is not having to worry about overcharging or over-discharging the battery because our integrated BMS (onboard smart Battery Management System) takes care of this for you by preventing it. Easy is having the integrated battery charge itself when the fan is plugged in and off. Easy is also having the BMS automatically perform routine cell maintenance on the battery when the charging process is complete and while the fan remains plugged in. Easy is the automatic switching between battery and a/c power that occurs when an a/c power source is introduced to or removed from the fan. Easy is having a well-balanced fan with an ergonomic handle to easily remove from the apparatus, deploy, and return to the apparatus.

Having an integrated battery and integrated power supply ensures you have dedicated power sources for the tool. Having an integrated smart BMS to monitor and maintain the battery ensures you have an optimized battery and reduces the risk of degradation. If you plug the unit in when not in use, you know the condition and state of the battery. Easy is not worrying where to make room on the apparatus for the external chargers, there are none. Easy is not having to figure out what external batteries are at what capacity, and which ones still need to be charged. While using hot-swappable batteries that can be used and shared among several tools is inviting, this adds complexity and more chance for things to go awry.

Our team likes to K.I.S.S. Easy is no extra stuff to monitor, maintain, or store, just a high-performing fan that has everything you need built-in. It is our goal to design simple easy-to-use tools that support your team by operating in the most highly effective manner possible.

VOLUMETRIC AIRFLOW, WHY IT’S IMPORTANT

Ventilation is the process of airflow entering a system, flowing through the system, then exiting the system. Volumetric airflow, commonly known as “CFM” or “m3/h”) is important because this is what feeds the airflow. The more air in, the more air out, and in ventilation, you want to maximize the “air out” part! When we test for fan effectiveness, measuring the velocity of air exiting a system is something we always do, because, in the simplest terms, that’s the “work” being done. Airflow into the system is also important much of the time in that the higher the volume, the more clean, cool air is introduced into the structure.

PRESSURE—IT’S IMPORTANT TOO

Positive pressure ventilation tries to maximize the airflow discussed above while driving up pressure inside the structure. When a pressure differential is present, there will always be air movement flowing from high pressure to low pressure until the pressure in the structure equals the external atmospheric pressure. Higher pressure inherently results in increased airflow as it naturally tries to equalize itself. When looking at pressurizing the structure, good entrance and exit points must be selected. Things such as the size of openings, external wind speed and direction, and pressure loss points (structural leakage) are examples of things to take into consideration with respect to the capabilities of your fan.

Teamwork is key

Volumetric airflow and pressure must work together as a team to deliver maximum fan effectiveness. In a multilevel structure, or even one level with the airflow path consisting of many corridors, the pressure generated from the PPV fan is driving the ventilation. The volumetric airflow contributes to this pressure, although it does not define it linearly among fans. The volumetric airflow works together with the pressure to contribute to the rate of flow at the exit point.

ENTRAINMENT—IT’S A REALLY BIG DEAL

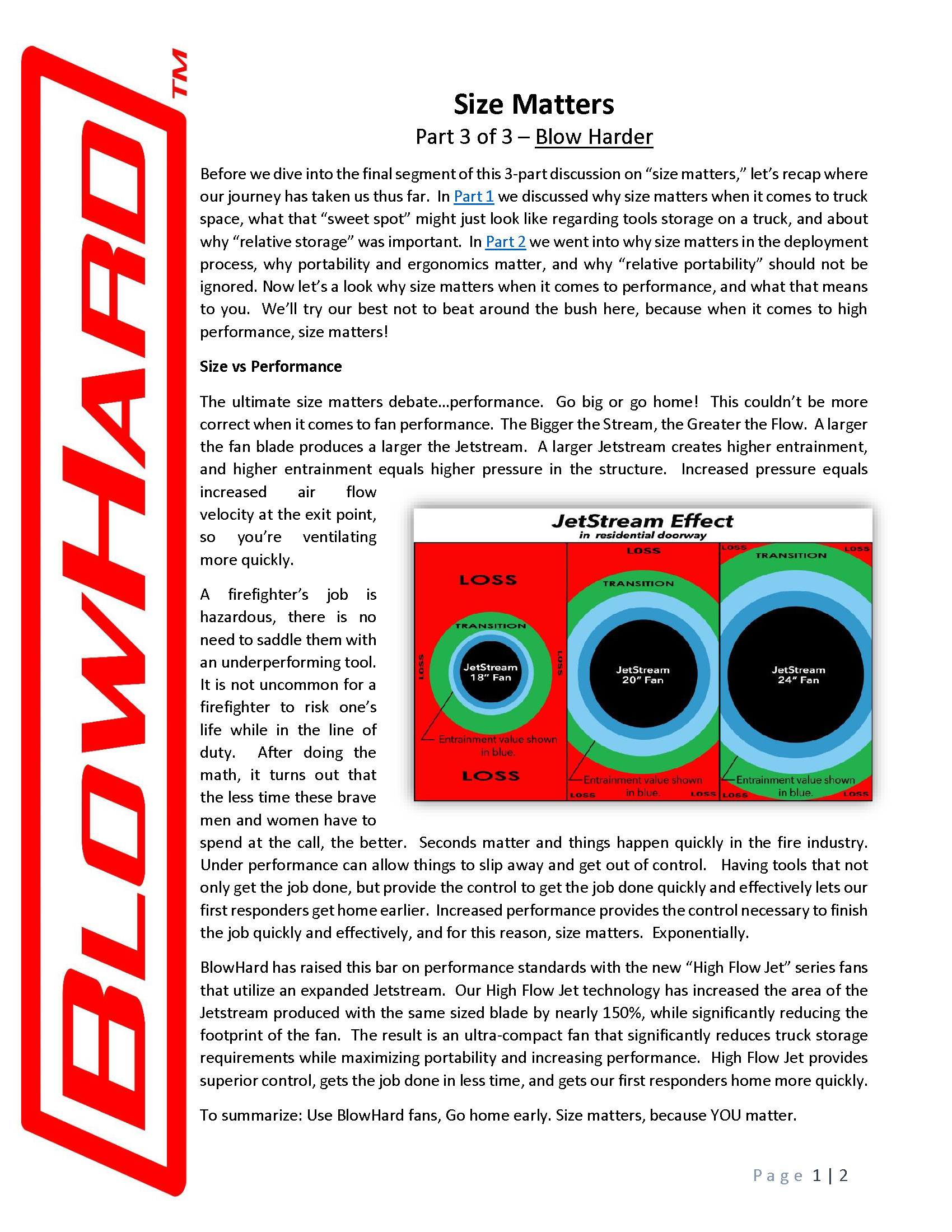

When air exits the fan, the edges of the air stream interact with the air surrounding it, causing it to also travel in the same direction. This is entrainment. By the time the air stream reaches/enters the structure, there is more air traveling in that direction (volume) than what exited the fan itself. Entrainment increases as velocity is increased. Expansion of the air stream with the same velocity also increases entrainment. Basically, increasing air molecules in the stream interacting with increased air molecules in the surrounding air increases entrainment. So, what’s the big deal about entrainment? An obvious answer would be increased volumetric airflow (CFM, m3/h, etc). And while this is true, another really important advantage of maximizing

When air exits the fan, the edges of the air stream interact with the air surrounding it, causing it to also travel in the same direction. This is entrainment. By the time the air stream reaches/enters the structure, there is more air traveling in that direction (volume) than what exited the fan itself. Entrainment increases as velocity is increased. Expansion of the air stream with the same velocity also increases entrainment. Basically, increasing air molecules in the stream interacting with increased air molecules in the surrounding air increases entrainment. So, what’s the big deal about entrainment? An obvious answer would be increased volumetric airflow (CFM, m3/h, etc). And while this is true, another really important advantage of maximizing

entrainment is increased pressure in the structure. PPV fans used a cone airstream for years. The concept behind this was to “seal” the entrance where the PPV fan was blowing in. And it made sense to prevent pressure from escaping through the very opening it was originating. The problem with using the cone method is oftentimes most of the airflow was dedicated to sealing the entrance and little was dedicated to building pressure. Any entrained air was also irrelevant using this method as it simply hit the wall of the structure.

BlowHard introduced using “Jet Technology” into the PPV application. This concept is using a tight cylindrical stream of air moving at a high velocity, all of which travels through the entrance. The seal in this case would be the entrained air or the expanded air movement in the same direction as the jet stream. The objective is to maximize the air entering the structure while “plugging the hole.” This proved to be a successful approach in that the BH-20 would outperform fans of a much higher volumetric airflow rating that used the cone technology. You can see this today as most PPV fans

are using some sort of Jetstream and marketing their ability to straighten the air.

BlowHard has since expanded on this technology with “High Flow Jet Technology.” Before expanding on this, let’s talk about what happens currently with PPV fans. When you force a lot of air through a shroud, turbulence is introduced when that stream exits the shroud, and some of the energy is absorbed by this turbulence in the form of vortexes. What this means is the resulting diameter of your stream is reduced. The BH-20 is a 20-inch fan, but the “real” Jetstream exiting the fan is likely somewhere around 18 inches. This is easily shown on this and all other fans with flow ribbon (a small strand of toilet paper works.) Fan law, in the most simple terms, says that volumetric airflow is directly related to area and power. This reduction in area in effect reduces the number of air molecules of the Jetstream edges engaged with the air molecules of the atmospheric air. This results in a smaller diameter stream at the entrance and less entrainment and thus having a direct impact on the ability to pressurize the structure. The 2nd generation of BlowHard PPV fans actually does the opposite, using this “High Flow Jet Technology.” What happens, in this case, is that as the air exits the shroud, it actually expands. The Quickee, also a 20-inch fan, has a Jetstream diameter of around 21 ½ inches right when it exits the shroud. This also can be shown/tested with a flow ribbon. This means, using the same explanation as above, higher entrainment, and thus higher pressure. And yes, the Quickee with the same power and blade length as the BH-20 will have increased fan effectiveness (pressure differential and higher velocity of airflow at the exit) of about 20%! The Commando, a 24-inch fan, uses the same technology, and one will significantly outperform two BH-20 PPV fans side by side (one low on the entrance, one high).

We always knew that entrainment was important, but it wasn’t until we did the testing above did we understand just how big a deal it was…is!! Man, we have fun, don’t we!!

WHY ERGONOMICS MATTER

When it comes to firefighting tools, performance is key. Firefighting tool manufacturers focus on performance benefits, as to firefighters themselves. And this makes sense, the tool should deliver the expected results. Unfortunately, when evaluating tools, the health and safety of the firefighter and the cost of insurance claims are often overlooked.

It’s really no surprise that fatigue increases the risk of work-related injury to firefighters. Ergonomic tools reduce this risk because they reduce the effort needed to deploy and operate the tool by reducing the stress placed upon one’s musculoskeletal system.

So how are BlowHard tools ergonomic?

1. We design our tools to be well-balanced. This allows the individual to increase and maintain proper posture while deploying and operating the tools. This also reduces or eliminates stress where an imbalanced tool would rest on your body while carrying, either by hand or with a strap.

2. The design of our handles and grips are such that the average person can grip comfortably in both design and angle. The placement of our handles and grips are such that it does not restrict the ability to maintain proper posture. This placement is also such that it reduces additional bodily impact while carrying.

BlowHard tools are designed to fit the firefighter as much as possible so that they are safer and more efficient in situations already mentally and physically demanding, providing more comfort and increased productivity. Ergonomics is an important consideration because the body of a firefighter experiences stresses caused by awkward posture and extreme temperature by the sheer nature of their job. This in turn affects their musculoskeletal system, making them more susceptible to a musculoskeletal disorder. We strive to reduce this risk. The benefits of this would include increased savings from fewer injuries, more productive and sustainable firefighters, fewer insurance claims, and increased morale.

If an injury results in a claim, the direct costs would include medical treatment, costs of prescriptions, wraps, braces, etc., and insurance premium increases. There would also be indirect costs, such as overtime to cover the injured, administration costs adjusting schedules, legal and/or investigation costs, training costs, etc. Furthermore, it has been stated that these indirect costs are 3-5 times more expensive than the direct costs.

PPV—ARM YOURSELF WITH KNOWLEDGE

Positive pressure ventilation (PPV) has become a very common practice in the fire industry, and as the benefits from it continue to become more documented and validated, its practice continues to grow worldwide. Evidence of this is seen in the number of different PPV fans now on the market, as well as emerging technologies in play. One big game-changer is the entrance of dual-powered fans entering the market. These fans can be run on battery or a/c, tend to be more portable and compact and use a cylindrical “jet” stream more suitable for the most common entranceway used in PPV, windows, and typical man doors. Advancements in stream technologies have impacted the industry and have added to the complexity of PPV fan selection. All of this information can make trying to figure out what to look for in a PPV fan daunting. Hopefully, this article will help shed some light on the subject.

When PPV was introduced to the industry, fans didn’t vary much, and they all used cone technology. With proper placement, each fan functioned in a similar manner, and volumetric airflow became an easy and valid way to gauge performance. A PPV-specific group was established at AMCA to recognize this. This group leveraged AMCA as a third-party industry tester to create a standardized test to rate the volumetric airflow of PPV fans. This was simple, unbiased, and great for the industry. Volumetric airflow often stated as “CFM” or “m3/h”, remains a common value looked at to determine the performance of a PPV fan.

In recent years things have evolved and the industry has shifted. Jet technology was introduced and has consistently outperformed cone technology at smaller, more commonly used pressure differential points, such as human doors and windows. Jet technology utilizes a concentrated high-pressure jet stream and this complete stream of air is dedicated to ventilation. A cone, with its rapidly expanded working area, significantly reduces working pressure at these common pressure differential points and wastes significant air volume impacting the wall around the door. Suddenly, a 10,000 CFM AMCA rated fan using jet technology was outperforming 13,000-14,000 CFM AMCA rated fans using the cone technology. With man doors being the primary ventilation point, the recognized performance of Jet Technology has resulted in the industry shift to Jet Technology. It is important to note that AMCA is a useful tool for comparing similar fan technologies, but should not be used as a comparison for different technologies. Because of these discrepancies, fan comparisons have been difficult for both the buyer and fan manufacturer.

Today’s marketing seems to be each company touting product capabilities, accurate or not, followed by the one-dimensional solution poised to sell it. In reality, fan effectiveness is not one-dimensional, but instead is a combination of things extending beyond the all-important fan performance, to how it interacts with and hopefully improves the overall performance of the firefighter. A firefighter’s workplace is often a state of emergency with intense conditions presenting challenges of an extreme nature physically and mentally, and at times life-threatening. The performance of a PPV fan (or any tool for that matter), should be evaluated from when the firefighter arrives on the scene to when the firefighter departs. While fan performance is a critical metric, it is not the only metric. Fan performance extends beyond simply turning fan A on to compare with fan B, already set up in a controlled environment in ideal conditions. Instead, fans arrive with the firefighter to a high-stress emergency situation. The firefighter must retrieve the fan(s) from the compartment on the truck. The firefighter must transport the fan to the desired ventilation entrance, or pressure differential point, oftentimes while carrying a host of other necessary tools or breathing apparatus. This may require walking some distance, overcoming obstacles, going up and/or downstairs, through doorways, through hallways, or alleys. I’ve seen a PPV fan carried up a ladder and deployed into a window from a rooftop. The firefighter must then set up the fan at the desired or required distance and angle needed to maximize ventilation efforts, then the fan must be started/turned on. The more quickly this all happens, the more quickly the firefighter can begin other required functions, making “response time” not only important but critical.

Given the extreme stresses in play, it is equally important that the firefighter has the confidence and freedom to know the running fan will ventilate the structure without additional efforts of issues and in a timely manner and allow them to focus on other needed tasks. Finally, when the situation is under control, and oftentimes the firefighters are mentally and physically exhausted, the fan must be transported back to the truck and placed back in the compartment without excessive exertion, strain, or injury. This is complete fan effectiveness.

Compactness is a fan effectiveness variable noted above. Space on a fire truck is a commodity, so a little goes a long way. The less room a fan requires, the better. This would include the size of the fan, as well as any external charging requirements the fan might have if hot-swappable batteries are used instead of fans containing high-capacity integrated batteries.

Weight, shape, size, balance, and carrying options all play into transporting the fan. A light-weight, well-balanced fan with handles designed to reduce stress while carrying make transporting the fan easier while reducing the risk of injury.

Setup and adjustment should be fast, simple, and precise. In high-stress emergency situations, firefighters are required to maximize efforts while reducing the time needed to do so. The placement and set-up of a PPV fan should be simple and require as little time as possible. Fans with flexible setback ranges allow for quick placement that takes little to no thought or measurements. Fans with brake systems that are easily accessible, release and set quickly, and have angle adjustments that can be accurately fine-tuned provide maximum entrainment value for rapid ventilation but require little time from the firefighter. In limited time emergency situations, this extra time saved could be the difference between life and death.

When using a PPV fan on the battery, it may be necessary to ventilate beyond the capacity of the battery. These situations require the PPV fan to be capable of running on a/c as well. The technology used to switch between battery and a/c is therefore important. Evaluation on whether or not it is automatic, or if ventilation is interrupted at any point, or if additional action must be taken is important. Fans that can switch from battery to a/c (and back) seamlessly and automatically without affecting ventilation are a benefit and becomes less the firefighter has to think or worry about. Taking it a step further, some fans have incorporated a blink-sequence for the LED path lighting that occurs when the fan battery has discharged the fan is no longer running. In a noisy environment where the fan cannot be heard running, it alerts the firefighter that action must be taken for continued ventilation. This allows for quick corrective action and reduces unneeded setbacks.

Thus far, the discussion has been on a variety of things to look for that can provide added value, the summation of which can make a big difference. But at the end of the day, the fan’s sole purpose for being there in the first place is providing ventilation. And firefighters have strived to understand what ventilation performance fans have, both from a budgetary and process perspective. So, let’s discuss fan effectiveness strictly from a ventilation perspective now.

Volumetric airflow is important when looking at ventilation because this is what feeds the airflow. Positive pressure ventilation (PPV) introduces pressure into this process to accelerate ventilation. To conduct positive pressure ventilation, you must select a specific point to generate working pressure in the structure. This requires a pressure differential point. This is the point where atmospheric pressure ends and systemic pressure begins. To generate working pressure, you must have a point where the fan can generate pressure without air escaping. The better you are able to generate working pressure, the more control you will have in controlling airflow through the structure. To better understand this, let’s explore a few scenarios:

- Example 1: Setting a fan up to blow across a warehouse structure in “open-air” will not create pressure for controlled air movement. Open-air movement simply creates air circulation. The air will circulate because there is no point where pressure generation or pressure differential can occur. You do not have a pressure differential point, you will not create pressure and work cannot be accomplished. Note: Open-air circulation has a place and can be useful in many industries but is not helpful in conducting positive pressure ventilation

- Example 2: Setting a fan upon a door opening that is excessively large, say 10X relative to the air stream will not “seal” the door. If the door is excessively large the air will easily escape from the edges of the door and you will not generate working pressure. This cannot work as a pressure differential point, you will not create pressure and work cannot be accomplished.

- Example 3: Setting up a fan on a door opening in which the stream of the fan covers more than 50% of the door area. The perimeters of the jet stream will entrain air to create pressure in the structure. The structure will have a differential pressure with which work can be done, flow paths can be created.

- The fan can be placed outside the structure blowing in to create positive pressure or inside the structure blowing out to create negative pressure.

It is important to note: You are not building pressure by closing all openings on the structure. A fan must be capable of generating a sufficient volume of air to build pressure with the desired flow paths open. Volumetric airflow and pressure must work together for true fan effectiveness with regard to ventilation performance.

Fan performance is a key metric for any battery-operated fan. Battery-operated fans have taken the approach of “jet” technology as it is able to build good pressure in the structure. Jet technology is a good option as it works well for man doors and windows. The size of the jet has a dramatic impact on the fan performance and battery life. Large area jets are intrinsically more efficient as the fan does not need to work as hard to create a high flow air stream and the jet stream is larger which results in higher volume entrainment with less power. Large jets enhance fan performance and/or extend battery operation time at a given level of performance. It would not be uncommon for a larger area PPV fan to outperform a smaller area PPV fan that has a higher measured CFM. It is important to balance the volumetric airflow with the maximized Jetstream area. This balance is a large contributor to fan effectiveness and should be considered. Recent tests done with fans using a similar jet technology have confirmed this when a 20-inch fan at 700W had a similar performance as an 18-inch fan at nearly 1000W and a higher claimed AMCA rated CFM.

With the latest fan and battery technology, battery-operated PPV fans have outperformed petrol-driven fans in the field. The combination of ease, performance, and space-saving designs you can expect to see in industry shift toward battery-operated PPV fans in the near future.

In recent years there has been a growing trend to selecting and using fans with jet technology. Does that mean the old cone technology is going away? The answer is… it shouldn’t. Each technology has its place. Cone is better for large openings, Jet is better for small openings. There are two key components, pressure and entrainment area.

The point where the air is driven into the structure is the point where pressure is generated. It is important to consider the opening where the air is driven into the structure, the point of pressure/pressure differential point.

The basic concept is that the size of the stream should be proportional to the size of the entrance point while maximizing pressure in the stream. For a jet, the opening size should be 1.5X-2.5X jet stream for entrainment, larger openings will work but blowback will be increased. For a cone, the shape of the cone should directly match the entrance point. Cone shapes will work better on a large opening such as a garage door or roll-up door. A jet shape will work better on smaller openings such as man doors or windows. However, choosing a roll-up door/cone over a man door is not as productive because the pressure of the cone is still limited. A high-volume jet on a proportionally sized entrance will provide high pressure and volume, providing higher flow control and more effective ventilation. That said, if the fire department calls primarily involve large structures with over 50% bay/roll-up doors, PPV fans using cone technology would be a good choice.

The most versatile fan would balance a large working area with jet technology, utilizing a large diameter Jetstream. Selecting a fan with jet technology with a larger diameter shroud would take advantage of a larger working area. Some companies have taken steps to develop technologies that focus on this very concept, expanding the working area beyond that of the shroud while maintaining a powerful Jetstream. This results in significantly larger entrainment and working areas while maintaining high pressures associated with jet technology. Fans using this technology inherently offer these benefits:

- Bigger jet

- Higher volumetric flow rates

- Higher entrainment

- Higher pressure

- Increased battery operating time

- Increase overall fan effectiveness

Portability and the ability to operate independently of additional power sources are key in the fire industry, as the environment and challenges for each call are unknown and unique. This makes petrol-driven and battery-driven fans very attractive. However, the safety concerns with petrol-driven fans with elevated CO levels along with portability and storage requirements have highlighted the ease of deployment and minimal maintenance requirements with battery-driven fans and have contributed to their uprise. Adding fuel to this fire, battery technology is ever-changing. High power density batteries available today provide the avenue to the energy needed to operate a PPV fan. Li-Ion is most commonly used in today’s battery-driven PPV fans and offers more energy transfer per volume. So, the question then becomes should you go with hot-swappable or High Capacity Integrated batteries?

Batteries are simple but at the same time a bit complicated. Let’s skim some basic battery concepts and explore choices.

As the power requirement of a battery increases, the battery performance decreases. Under continuous high stress, the battery gets hotter and the life decreases. Performance and capacity will vary depending on the cell configuration.

Batteries have a “C” rating. This is the amount of power a battery can discharge.

- Consider a battery pack which is 200 Watt-Hours.

- At 1C (Capacity X 1)

- The battery will deliver 200Wh X 1C = 200W

- The approximate battery run time will be 200Wh/200W = 1 Hour

- At 2C (Capacity X 2)

- The battery will deliver 200Wh X 2C = 400W batteries will see high stress/reduced life with continuous use

- The approximate battery run time will be 200Wh/400W = ½ Hour

- Consider a battery pack which is 1000 Watt-Hours.

- At .2C (Capacity X 1)

- The battery will deliver 1000Wh X .2C = 200W

- The approximate battery run time will be 1000Wh/200W = 5 Hours

- At 1C (Capacity X 1)

- The battery will deliver 1000Wh X 1C = 1000W

- The approximate battery run time will be 1000Wh/1000W = 1 Hour

- At 2C (Capacity X 2)

- The battery will deliver 1000Wh X 2C = 2000W batteries will see high stress/reduced life with continuous use.

- The approximate battery run time will be 1000Wh/2000W = ½ Hour

Hot-swappable batteries are capable of providing extended run time by changing the batteries out but have limited power capability which limits performance. This can be detrimental when high performance is required. The extended runtime also requires the fan to be serviced and ventilation will be interrupted from this fan during this service. Finally, hot-swappable batteries experience high stress even at limited performance. Let’s explore a scenario using hot-swappable batteries.

- Capacity

- Consider 6 battery packs which are 200Wh each will provide a total capacity of 1200Wh.

- Performance

- If 2 packs are used at a time the total capacity is 400Wh.

- A reasonable discharge rate to prevent overheating is 1.5C or 400Wh X 1.5C = 600W.

- Run Time

- Operating this configuration at 600W provides: 1200Wh/600W = 2-hours of run time.

- With a charge time of 4-hours, it is not reasonable to assume a continuous use of batteries unless 10+ batteries are being swapped and recharged.

High Capacity Integrated (HCI)batteries are larger. This inherently means higher performance capabilities at the same “C” rating. This also means that an HCI battery with an equivalent “total” capacity can provide equal runtimes at the same power (2-hours @ 600W) with significantly reduced battery stress (extends battery life) and while providing continuous, non-interrupted ventilation. And if performance is required, fans using HCI batteries can produce significant power such that a properly designed fan can perform like a gasoline-driven fan. This expands the usability for an HCI battery-driven fan to scenarios not possible before, such as realistic ventilation of large warehouses and successful pressurization of high-rise stairwells. Let’s explore a scenario using High Capacity Integrated batteries.

- Capacity

- Consider 1 battery pack which is 1200Wh.

- Performance

- A reasonable discharge rate to prevent overheating is 1.5C or 1200Wh X 1.5C = 1800W (3X Hot-Swappable performance.)

- Run Time

- Operating this configuration at 600W provides: 1200Wh/600W = 2-hours of run time.

- Operating this configuration at 1800W provides: 1200Wh/1800W = 40-minutes of run time.

With batteries come charging needs, and there are differences in charging requirements between hot-swappable batteries compared to HCI batteries that should be considered. Charging hot-swappable batteries requires additional external chargers. This significantly increases the footprint of the storage and adds complexity to the wiring system. The limited performance will require longer runtimes to achieve similar ventilation, which may require an increased number of batteries and external chargers.

Fans using HCI batteries also use an integrated charger built into the fan, so charging simply requires the fan to be plugged in. This significantly reduces the footprint of the complete system on the truck. Some companies incorporate fast charging from 0-90% battery capacity. This means in 2 hours nearly all battery capacity is restored and available for use. A high capacity battery allows the fan to be charged and reused quickly with a partial state of charge in excess of lower capacity batteries at full charge and can be done without damaging the battery.

Hot-Swappable vs High Capacity Integrated Battery Summary:

- HCI batteries have extended runtime without additional setup/swapping.

- HCI batteries have higher performance.

- HCI batteries reduce battery stress/extend battery life at equivalent power.

- HCI batteries have a higher “fast charge” capacity for quick turnaround use.

- HCI batteries do not require additional truck space for charging.

- Combine fans using jet technology and expanded area with HCI batteries for continuous runtimes as high as 8-10 hours at an equivalent performance lower area lower volume jet fans.

- Hot Swappable batteries can be charged when the fan is running. When considering charge rates, 10+ batteries and a dedicated person is required for continuous swapping to ensure continuous fan operation with downtime during battery swapping.

Finally, as you define your performance needs, hands-on testing to see how fans align with your needs is the best approach. Being able to pick it up, carry it, set it up, see how it fits in the truck compartment, etc., can shed light on what fans truly have the extra values. Side-by-side comparison performance tests are an important part of determining ventilation performance, and we recommend this be done by the fire departments as they evaluate fans. A structure resembling a structure size common for your area, with an entrance you would typically use (likely human door), and an exit point similar to what you would typically use that is not directly across from the entrance point that can be opened, like another human door or window, is best. Also needed is a low-pressure differential manometer and an anemometer to measure wind speed. Using the differential manometer, you can measure the difference in pressure between atmospheric and systemic pressures. Then using the anemometer, you can measure the wind speed at the exit point. You will see that as pressure increases, as does the wind speed at the exit point. This method is a great way to determine performance differences as well as validate/debunk manufacturer claims.

Trying to make your way through the decision process for what tools to purchase and use is often difficult and daunting for the average person. Add the high stress, physically and mentally draining conditions, oftentimes with lives on the lines, when a firefighter reaches for a tool, it had better perform as advertised on all levels. In this article, we outlined many things to consider when choosing which PPV fan you want in the hands of you and your team. And while all fire departments may vary slightly in their strategies and needs, performance is one thing that tends to be common. We hope this helps you decide what performance you’re looking for, and what to look for in a fan in order to get the most value. And happy ventilating!

Why exaggerated numbers are a disservice to the fire industry

Marketing. Convincing someone they need your product, letting the world know how badass you are.

We do it, every successful business does it. It’s a necessary component of the business. However, making claims having to do with the performance that is not actually achievable by the product they are made about is, generally speaking, unethical. But the firefighting industry is unique. Lives can depend on tools performing as advertised. And with the number of tools out there combined with the number of companies making those tools, it would be next to impossible to truly test (verify) all that is advertised.

At BlowHard, we do feel it is crucial we advertise exactly what is achievable with our products, and nothing more. Unfortunately, with the lack of standards for testing some things, lines get grayed. We still try to advertise honestly. But what we are referring to are companies who exaggerate the ability of their tools to completely unrealistic values—the tool would never get there… ever. This is a complete disservice to the industry, it is unethical, to put it mildly, and companies doing this should be called out for it. The men and women who put their lives on the line daily to protect and serve our communities deserve better.

We demand it and will continue to lead by example.

All in the Numbers

We were talking about ways to give meaningful data to the industry in an effort to assist in meaningful decisions. As we’ve pointed out, CFM or m3/h just don’t tell you how effective a PPV fan is going to be. Measurements such as pressure built in a structure, velocity at the exit point are excellent in painting more of a picture. We have also discussed the importance of ergonomics. And then we started talking about what “High Flow Jet Technology” brings to the picture. Really, when you look at such performance, it is impressive. But when you look at that same performance and combine it with the weight of the fan, or the size of the fan…it just begs for new metrics to be considered; Performance/weight ratio. Performance/footprint ratio.

Let us know what you think!

Add your geek

The Next Revolution Is Here

The Next Revolution Is Here